Gasketing

Seals and sealing systems are widely used in various manufacturing industries to provide protection from moisture, dust and dirt. With the improvement of production technology items may take more complex forms. Consequently, seals should provide more reliable protection and the ability to accurately applied on complex trajectories, combined with the low cost.

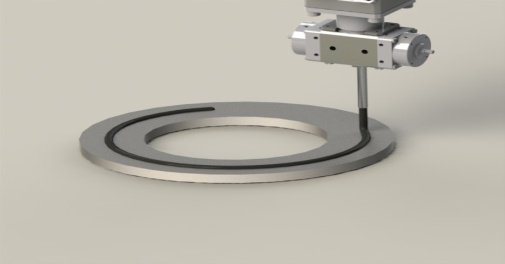

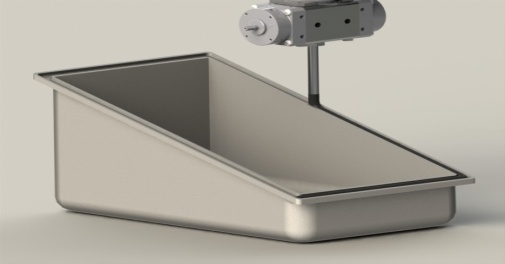

The application of conventional bonded seals are not always satisfy these conditions. This prompted the development of the technology GASKETING, ie obtaining seal in place with the use of foam (FIPFG) or not foam (FIPG) polymer.

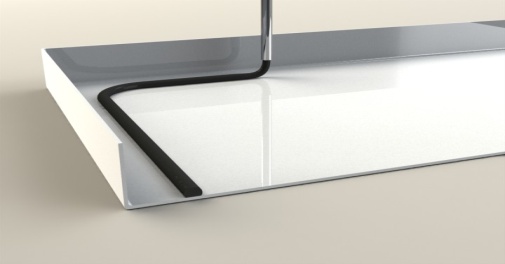

The technology is in the precise application on the programmed path on the dosage and mixing of two-component (possibly multi-component ) polyurethane or silicone composition . Components reacting mixture after mixing to form a surface or recess of the product seal outer protective film ( surface crust or shell ) .

Seal obtained by this technology , provides a degree of integrity and protection of IP54- 67 and has a number of advantages:

- is seamless , eliminating joints and trim , typical for other seal types , and is guaranteed to prevent the ingress of moisture and dust from entering the unit ;

- allows to achieve the best sound and vibration absorption sound insulation ;

- increased levels of automation , reducing labor costs ( only one operator is required) ;

- can be accurately applied to the surface of all types and in different paths ;

- high adhesion of the seal to the product ;

- cost 3-10 times cheaper molded .

Our staff is ready to answer any question regarding the implemented services.

Also you can send us your application and attach diagram drawing product that you want.